NAS NW400; High Corrosion Resistant Ni-Cu Alloy

Characteristics of NAS NW400

An alloy including copper and nickel, NAS NW400 (NW 4400, UNS N04400), comparable to Alloy 400, shares in the noble properties of copper and passivation of nickel to provide excellent corrosion resistance. It is therefore used in seawater desalination systems, heat exchangers and marine structure jackets.

Chemical Composition

(%)

| - | C | Si | Mn | S | Ni | Cr | Fe |

| JIS H 4551 NW4400 |

≦0.30 | ≦0.5 | ≦2.0 | ≦0.025 | ≧63.0 | 28.0~34.0 | ≦2.5 |

| NAS NW400 | 0.1 | 0.1 | 1.0 | 0.01 | 65 | 31 | 1.5 |

Corresponding Standard

Corresponding standards are as follows;

JIS H 4551 / NW4400

ASTM B 127 / UNS N04400

ASME SB-127 / UNS N04400

AMS 4544

Mechanical Properties

| Heat treatment | 0.2% Proof stress (N/mm2) |

Tensile strength (N/mm2) |

Elongation (%) |

Hardness (HV) |

|

| JIS H 4551 NW4400 |

Annealed | ≧195 | ≧480 | ≧35 | - |

| NAS NW400 (12 mm thick) |

Annealed | 209 | 513 | 52 | 131 |

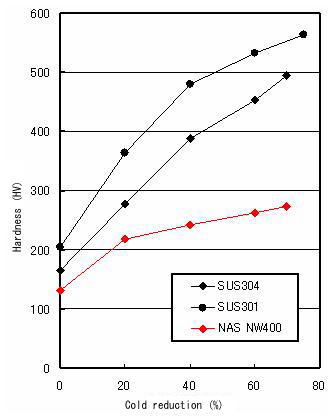

Work Hardening Behavior

NAS NW400 is far less hard than Type 301 and Type 304, making bending and other such processes easy to perform.