NAS601; Ni Base Heat/Oxidation Resistant Alloy

Characteristics of NAS 601

A nickel base alloy also containing chromium and aluminum, NAS 601 (NCF 601, UNS N06601), comparable to alloy 601, is resistant at high temperatures, and has powerful resistance to oxidation, carburization and sulfurization. It excels particularly in exfoliation resistance in repeated oxidation applications with a high temperature variation, and is therefore used in various parts for heat treatment furnaces, diesel vehicle glow plugs and the like.

Chemical composition

(%)

| - | C | Si | Mn | P | S | Ni | Cr | Cu | Al |

| JIS G4902 NCF601 |

≦0.10 | ≦0.50 | ≦1.00 | ≦0.030 | ≦0.015 | 58.00~ 63.00 |

21.00~ 25.00 |

≦1.00 | 1.00~ 1.70 |

| NAS 601 | 0.03 | 0.20 | 0.50 | 0.005 | 0.001 | 59.8 | 22.4 | 0.02 | 1.30 |

Corresponding Standard

Corresponding standards are as follows;

ASTM B168 / UNS N06601

ASME SB168 / UNS N06601

SAE AMS 5870

JIS G4902 / NCF601

Mechanical Properties

| Grade | 0.2% Proof stress (MPa) |

Tensile strength (MPa) |

Elongation (%) |

Vickers's hardness (HV) |

| JIS G4902 / NCF601 | ≧195 | ≧550 | ≧30 | - |

| NAS 601 | 385 | 763 | 40 | 197 |

Oxidation Resistance

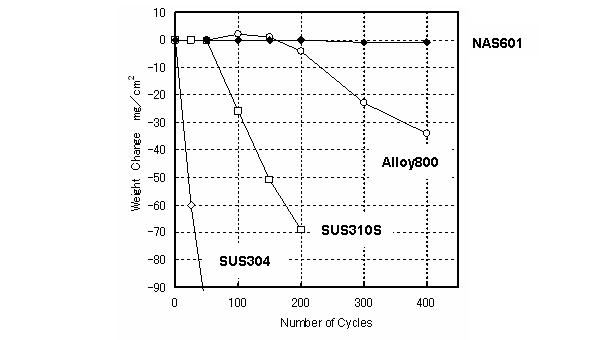

Cyclic oxidation test results at 1000℃ in air.

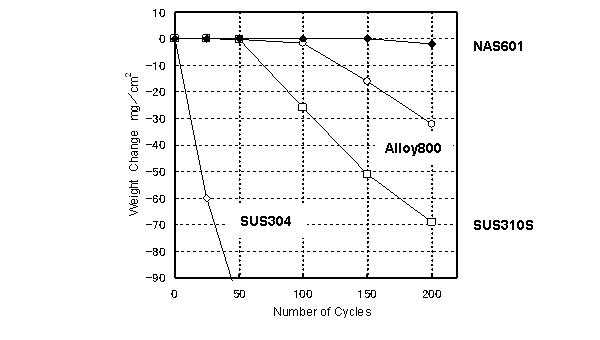

Cyclic oxidation test results at 1100℃ in air.

One cycle: 30 minutes at test temperature followed by 10 minutes cooling