NAS NW22; High Nickel Corrosion Resistant Alloy

Characteristics of NAS NW22

NAS NW22 is a Ni-Cr-Mo alloy with excellent pitting, crevice corrosion, and stress corrosion cracking resistance in both oxidizing and reducing atmospheres. Based on these features, NAS NW22 is widely used in materials under severe environments such as flue gas desulphurization apparatus, pulp and paper industry, and waste treatment plants.

Chemical Composition

(%)

| C | Si | Mn | P | S | Ni | Cr | Mo | Fe | Co | W | V | |

| NAS NW22 | 0.004 | 0.04 | 0.31 | 0.008 | 0.0005 | Bal | 21.2 | 13.9 | 4.5 | 0.01 | 3.0 | 0.01 |

Corresponding Standard

ASTM B575 / UNS N06022

ASME SB575 / UNS N06022

JIS H4551 / NW6022

Mechanical Properties

| 0.2% Proof stress (MPa) |

Tensile strength (MPa) |

Elongation (%) |

Hardness (HRB) |

||

| NAS NW22 | Hot rolled material (12mm thick) | 367 | 744 | 73 | 84 |

| Hot rolled material (8mm thick) | 365 | 752 | 69 | 84 | |

| Hot rolled material (3mm thick) | 383 | 782 | 57 | 86 |

Physical Properties

| Temperature(℃) | Properties | |

| Density | RT | 8.69 g/cm3 |

| Melting point | 1325~1372 ℃ | |

| Electrical resistivity | RT | 1.14 μΩ・m |

| Coefficient of thermal expansion | 20~100 20~200 20~300 20~400 20~500 20~600 20~700 20~800 20~900 20~1000 |

12.4 μm/m・℃ 12.4 μm/m・℃ 12.6 μm/m・℃ 13.1 μm/m・℃ 13.7 μm/m・℃ 14.2 μm/m・℃ 14.8 μm/m・℃ 15.3 μm/m・℃ 15.9 μm/m・℃ 16.4 μm/m・℃ |

| Young’ modulus | RT | 204 GPa |

| Modulus in torsion | RT | 78.8 GPa |

Thermal properties

| Temperature (℃) |

Specific heat (J/kg・℃) |

Thermal conductivity (W/m・℃) |

Thermal diffusivity (m2/s) |

| 25 | 440 | 10.6 | 2.8×10-6 |

| 100 | 469 | 12.5 | 3.1×10-6 |

| 200 | 487 | 14.7 | 3.1×10-6 |

| 300 | 502 | 16.5 | 3.8×10-6 |

| 400 | 507 | 18.0 | 4.1×10-6 |

| 500 | 522 | 20.7 | 4.6×10-6 |

| 600 | 549 | 22.7 | 4.8×10-6 |

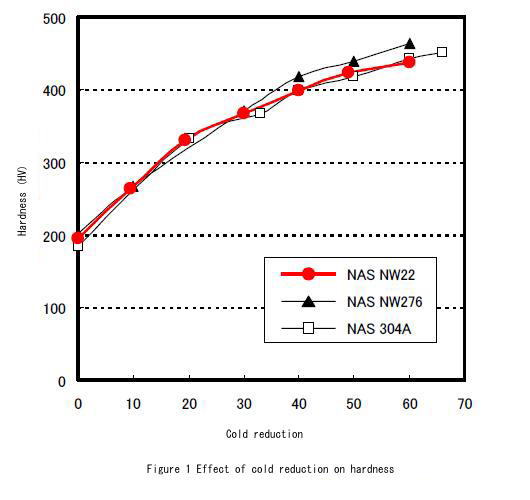

Workability

Figure 1 shows the effect of cold reduction on hardness.

Heat Treatment

The solution treatment temperature of NAS NW22 ranges from 1150 to 1170℃. Rapid cooling of the alloy is necessary after heating.

Corrosion Resistance

Pitting Resistance

| Grades | Critical pitting temperature [CPT] (℃) | |

| 6%FeCl3 + 1%HCl solution (ASTM G48 Method C) |

Green death solution | |

| NASNW22 | >120 | >120 |

| NASNW276 | >120 | >120 |

| NAS254N | 80 | 80 |

| NAS329J3L | 50 | 45 |

| SUS316L | 10 | 25 |

Crevice corrosion resistance

| Grades | Critical crevice corrosion temperature [CCT] (℃) | |

| 6%FeCl3 + 1%HCl solution (ASTM G48 Method D) |

Green death solution | |

| NASNW22 | >100 | 110 |

| NASNW276 | 100 | 110 |

| NAS254N | 40 | 15 |

| NAS329J3L | 25 | 30 |

| SUS316L | < 0 | < 0 |

Test condition ①ASTM G48 Method C :Test duration of 72 hours

②ASTM G48 Method D :Test duration of 72 hours with multi crevices

③Green death solution immersion test:Test duration of 24 hours

Test solution: 7%H2SO4+3%HCl+1%FeCl3+1%CuCl2

Multi crevice method was applied to crevice corrosion test.

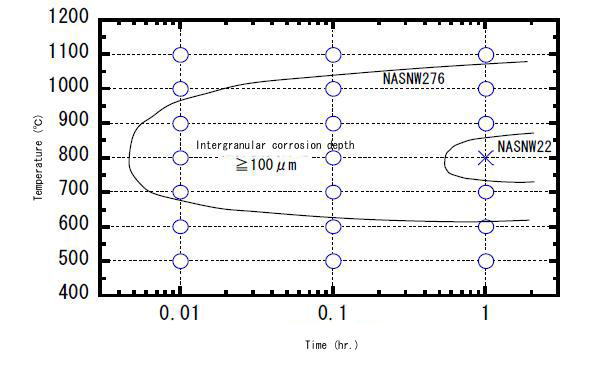

Intergranular corrosion resistance

Test condition:ASTM G28 Method A

24 hours of test duration in boiling 50%H2SO4‐Fe2(SO4)3solution

Stress Corrosion Cracking Resistance

| Grades | MgCl2Concentration (Boiling temperature) | |||||

| 20% (108) |

25% (110) |

30% (115) |

35% (126) |

38% (134) |

42% (142) |

|

| NASNW22 | ○ | ○ | ○ | ○ | ○ | ○ |

| NASNW276 | ○ | ○ | ○ | ○ | ○ | ○ |

| NAS254N | ○ | ○ | ○ | ○ | ○ | × |

| NAS329J3L | ○ | ○ | × | × | × | × |

| SUS316L | ○ | × | × | × | × | × |

○: no SCC, ×: SCC

Test condition: U bend specimen immersed in boiling MgCl2 solution for 300 hours.

Acid corrosion resistance

| Grades | Temperature (℃) |

Concentration (%) |

Corrosion rate (g/m2・hr) | ||||

| NASNW22 | NASNW276 | NAS254N | NAS329J3L | SUS316L | |||

| H2SO4 | 80 | 5 | 0.01 | 0.02 | 0.02 | 0.00 | 1.10 |

| 10 | 0.02 | 0.03 | 0.02 | 0.14 | 2.92 | ||

| 20 | 0.02 | 0.04 | 1.16 | 3.33 | 20.1 | ||

| 40 | 0.04 | 0.06 | 1.78 | 250.5 | 291.3 | ||

| 60 | 0.47 | 0.08 | 1.86 | 263.1 | 72.0 | ||

| 80 | 0.34 | 0.03 | 2.82 | 90.4 | 11.1 | ||

| Boiling | 5 | 0.14 | 0.10 | 1.43 | 0.61 | 5.45 | |

| 10 | 0.25 | 0.16 | 2.49 | 3.30 | 18.0 | ||

| 20 | 0.72 | 0.33 | 6.18 | 76.2 | 108.7 | ||

| 40 | 3.24 | 1.44 | 21.0 | 271.7 | 297.8 | ||

| HCl | 80 | 0.1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 |

| 1.0 | 0.00 | 0.02 | 0.00 | 0.01 | 2.45 | ||

| 2.0 | 0.01 | 0.03 | 3.15 | 19.0 | 6.66 | ||

| 3.0 | 0.03 | 0.33 | 12.8 | 51.5 | 13.6 | ||

| Boiling | 0.1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 | |

| 1.0 | 0.13 | 0.23 | 0.13 | 4.82 | 6.32 | ||

| 2.0 | 1.32 | 0.91 | 27.8 | 56.7 | 33.6 | ||

| 3.0 | 3.63 | 1.64 | 54.2 | 145.2 | 69.1 | ||

Test condition: Test duration of 24 hours