NAS NW276; High Nickel Corrosion Resistant Alloy

Characteristics of NAS NW276

Providing superior corrosion resistance in both oxidizing and reducing environments, NAS NW276 is an exceptional alloy made of nickel, chromium and molybdenum. Carbide precipitation is suppressed in the heat-affected zone during welding due to the reduction of carbon and silicon content, further improving the corrosion resistance. These features make NAS NW276 a popular alloy for use in materials subjected to severe environments such as found in chemical plants.

Chemical Composition

(%)

| - | C | Si | Mn | P | S | Ni | Cr | Mo | Fe |

| Example | 0.003 | 0.01 | 0.51 | 0.008 | 0.0005 | Bal | 15.4 | 16.6 | 5.6 |

Corresponding Standard

ASTM B575 / UNS N10276

ASME SB575 / UNS N10276

JIS H4551 / NW0276

Mechanical Properties

| - | - | 0.2% Proof Stress (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

Hardness (HRB) |

| Example | Hot Rolled Plate 14mm | 372 | 763 | 71 | 83 |

| Hot Rolled Plate 12mm | 319 | 738 | 76 | 83 | |

| Cold Rolled Sheet 2mm | 366 | 785 | 61 | 86 |

Corrosion Resistance

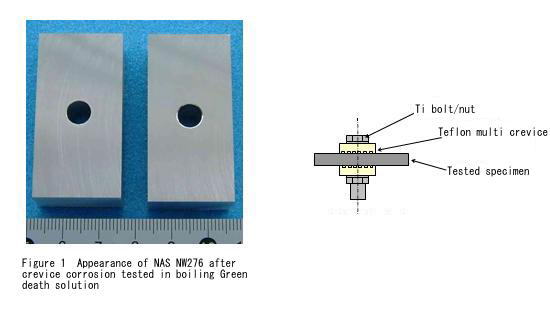

As an example of corrosion resistance of NAS NW276, crevice corrosion resistance in boiling Green death solution (Strong acid + oxidizing environment) is shown below. NAS NW276 shows no crevice corrosion in this solution to show superior corrosion resistance.

*Green death solution: 7%H2SO4+3%HCl+1%FeCl3+1%CuCl2

Test condition: Multi crevice made of Teflon was used for immersion test in boiling solution (boiling temperature of 105℃) for 24 hours.