NAS 301-K3;High Workability Stainless Steel for Springs

Characteristics of NAS 301-K3

1. Specification of springs for Type 301 is satisfied.

2. Following properties are characterized comparing normal grade of springs.

(1) Surface roughness and micro cracks are improved after working compared with conventional materials.

(2) Etched surface becomes sooth.

Chemical Composition

(%)

| - | C | Si | Mn | P | S | Ni | Cr | Remark |

| NAS 301-K3 | ≦0.15 | ≦1.00 | ≦2.00 | ≦0.030 | ≦0.030 | 6.00 ~8.00 |

16.00 ~18.00 |

Same as Type 301 in JIS G4305 and G4313 |

| Example | 0.09 | 0.86 | 0.80 | 0.030 | 0.002 | 6.42 | 16.55 |

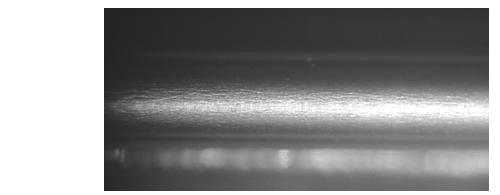

Smoothness at bended surface

Surface after bending of H finish material with 0.2 mm thick is shown in Table 1. Smoothness at bended surface is improved and micro cracks are less.

NAS 301-K3

|

|

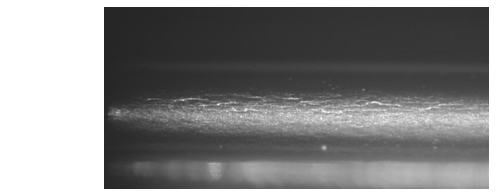

Surface after bending of standard Type 301 stainless steel

|

|

Application

It is suitable for various application requiring workability and surface smoothness after working.