NAS 304-K3 Cold Working Stainless Steel for Springs

Characteristics

Following properties are characterized comparing with conventional SUS304 for springs.

(1) Possible to apply large working with little surface roughness owing to large elongation.

(2) Easy to get smooth surface after etching caused by fine grain size

Chemical Composition

(%)

| - | C | Si | Mn | P | S | Ni | Cr | Remark |

| NAS 304-K3 | ≦0.08 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 8.00 ~10.50 |

18.00 ~20.00 |

Equivalent of JIS G4305 SUS304 |

| Example | 0.04 | 0.54 | 0.91 | 0.031 | 0.002 | 8.06 | 18.15 |

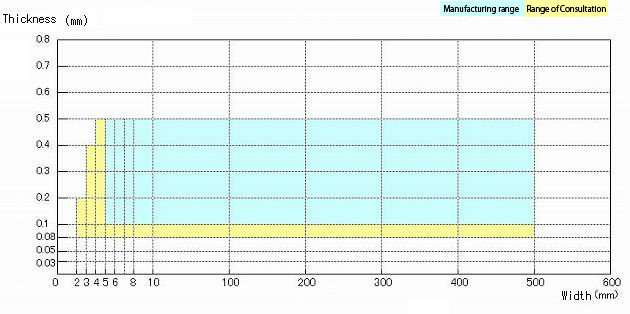

Product Range

Size : Thickness 0.08-0.50mm, Width 5-500mm

Finish : 1/2H、3/4H(Consultation necessary)

Mechanical Property and Workability

Mechanical properties and workability of 0.2mm thick and 1/2H finish NAS304-K3 is shown in Table1.

NAS304-K3 shows large elongation and high Erichsen value.

Table 1 Mechanical Property and Workability

| Grade | Thickness (mm) |

Finish | Tensile Strength (MPa) |

Elongation (%) |

Hardness (HV) |

Erichsen Value |

| NAS304-K3 | 0.2 | 1/2H | 807 | 51 | 236 | 10.5 |

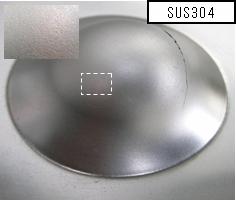

Surface Smoothness after Working Test

Surface smoothness of 0.2mm thick and 1/2H finish materials after Erichsen test is shown below.

Improved surface smoothness is observed in NAS304-K3 comparing with conventional SUS304.

|

|

Application

Various application requiring workability and surface smoothness after working.

Manufacture of the product range