NAS 74N; Corrosion Resistant Super Duplex Stainless Steel

Characteristics of NAS74N:

A super duplex stainless steel with a pitting resistance equivalent (PRE) of more than 40, NAS 74N provides excellent corrosion resistance and strength properties. Compared to UNS S32205(SUS 329J3L) and SUS 329J4L, NAS 74N offers superior localized corrosion resistance and is therefore suitable for use in chemical plants, seawater desalination plants and other such harsh chloride ion containing environments.

Chemical Composition

(%)

| - | C | Si | Mn | P | S | Ni | Cr | Mo | N | Cu | PRE*) |

| ASTM A240/ UNS S32750 |

≦0.030 | ≦0.80 | ≦1.20 | ≦0.035 | ≦0.020 | 6.0~ 8.0 |

24.0~ 26.0 |

3.0~ 5.0 |

0.24~ 0.32 |

≦0.50 | |

| EN 10088/ 1.4410 |

≦0.030 | ≦1.00 | ≦2.00 | ≦0.035 | ≦0.015 | 6.0~ 8.0 |

24.0~ 26.0 |

3.0~ 4.5 |

0.24~ 0.35 |

- | |

| NAS 74N | 0.015 | 0.30 | 0.70 | 0.020 | 0.0005 | 6.90 | 25.00 | 3.75 | 0.27 | 0.07 | 41.8 |

*)PRE = %Cr + 3.3×%Mo + 16×%N

Comparable Standard;

Designated standard is as follows;

ASTM A240 / UNS S32750 ASME SA240 / UNS S32750 EN10088 / 1.4410

Physical Properties

| Specific resistivity (μΩ/cm) |

Thermal conductivity (W/m・K) |

Specific heat (kJ/kg・K) |

Coefficient of thermal expansion [20~100℃] (x10-6/℃) |

Young's modulus (x104 MPa) |

Ferromagnetism |

| 82 | 13.0 | 0.45 | 13.4 | 19.7 | Yes |

Mechanical Properties

| - | 0.2% Proof stress (MPa) |

Tensile strength (MPa) |

Elongation (%) |

Hardness (HV) |

| ASTM A240/UNS S32750 | ≧550 | ≧795 | ≧15 | ≦310 |

| EN10088/1.4410 | ≧530 | 730~930 | ≧20 | - |

| Hot rolled sheet, 8mm thick | 989 | 1057 | 25 | 332(HV) |

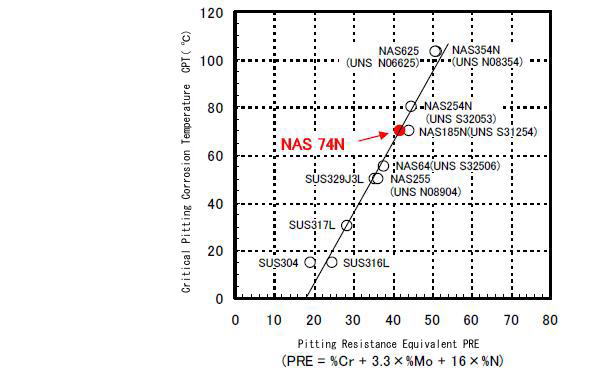

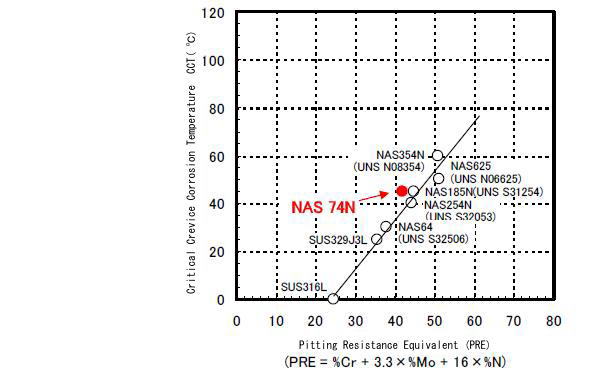

Corrosion Resistance

NAS 74N has excellent localized resistance against pitting and crevice corrosion as well as superior acid resistance in comparison with conventional austenitic stainless steels such as Type 304 and SUS 316L and such duplex stainless steels as NAS 329J3L (UNS S32205) and SUS 329J4L.

Pitting Corrosion Resistance:

Test condition:ASTM G48 Method C

Test solution:6%FeCl3 + 1%HCl Solution

Test duration:72hrs.

Crevice Corrosion Resistance

Test condition:ASTM G48 Method D

Test solution:6%FeCl3 + 1%HCl Solution

Test duration:72hrs.

Acid Corrosion Resistance

Test duration: 24hrs.

Corrosion rate in various acids

| - | Concentration | Temperature | Corrosion Rate(mm/y) | |||

| NAS 74N | NAS 64 | SUS329J3L | SUS316L | |||

| H2SO4 | 10% | Boiling | 2.25 | 3.64 | 3.70 | 19.7 |

| HCl | 1% | Boiling | 0.02 | 0.03 | 5.41 | 6.94 |

| HNO3 | 60% | Boiling | 0.06 | 0.08 | 0.11 | 0.17 |

| H3PO4 | 80% | Boiling | 2.83 | 4.99 | 5.52 | 25.0 |

| CH3COOH | 80% | Boiling | <0.01 | <0.01 | <0.01 | <0.01 |