NAS 625; High Nickel Corrosion and Heat Resistant Alloy

Characteristics of NAS 625

A solution strengthened nickel alloy with molybdenum and niobium added to the nickel-chromium base, NAS 625, comparable to alloy 625, provides superior corrosion and heat resistance. Uses include parts in chemical and garbage incinerator plants.

Chemical composition

(%)

| - | C | Si | Mn | P | S | Ni | Cr | Mo | Al | Ti | Fe | Co | Nb | Ta |

| ASTM B443 UNS N06625 |

≦0.10 | ≦0.50 | ≦0.50 | ≦0.015 | ≦0.015 | ≧58.00 | 20.0~ 23.0 |

8.0~ 10.0 |

≦0.40 | ≦0.40 | ≦5.0 | ≦1.0 | 3.15~4.15 | |

| JIS G4902 NCF625 |

≦0.10 | ≦0.50 | ≦0.50 | ≦0.015 | ≦0.015 | ≧58.00 | 20.00~ 23.00 |

8.00~ 10.00 |

≦0.40 | ≦0.40 | ≦5.00 | - | 3.15~4.15 | |

| NAS 625 | 0.02 | 0.10 | 0.08 | 0.010 | 0.001 | 61.73 | 21.60 | 9.00 | 0.22 | 0.24 | 3.32 | 0.02 | 3.65 | |

Corresponding standard

ASTM B443 / UNS N06625

ASME SB443 / UNS N06625

JIS G4902 / NCF625

Mechanical properties

| - | 0.2% Proof stress (MPa) |

Tensile strength (MPa) |

Elongation (%) |

Hardness (HV) |

| ASTM B443 UNS N06625 (solution annealed) |

≧276 | ≧690 | ≧30 | - |

| JIS G4902 NCF 625 (Solution annealed) |

≧275 | ≧690 | ≧30 | - |

| NAS 625 As cold rolled |

392 | 832 | 57 | 197 |

Corrosion resistance

Test condition: 24 hrs in 7%H2SO4+3%HCl+1%FeCl3+1%CuCl2

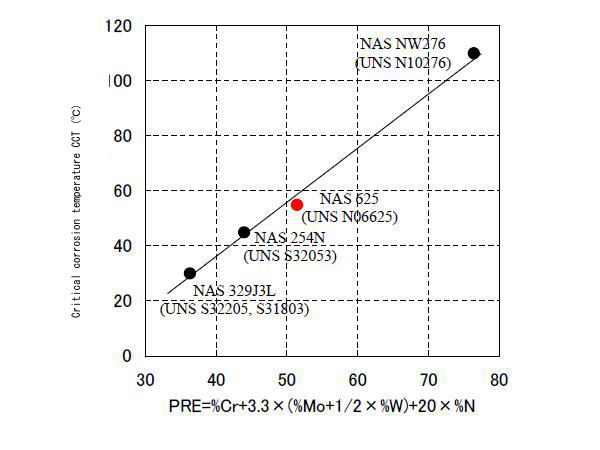

Crevice corrosion resistance