NAS NM17; Super Non-Magnetic Soft Stainless Steel.

Characteristics of NAS NM17

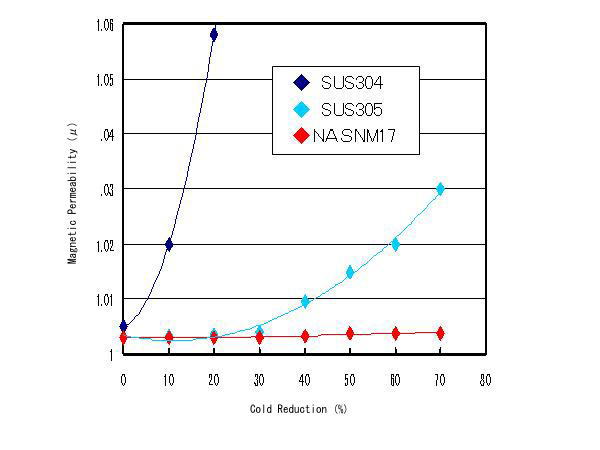

・NAS NM17 holds non magnetism even it is much cold worked.

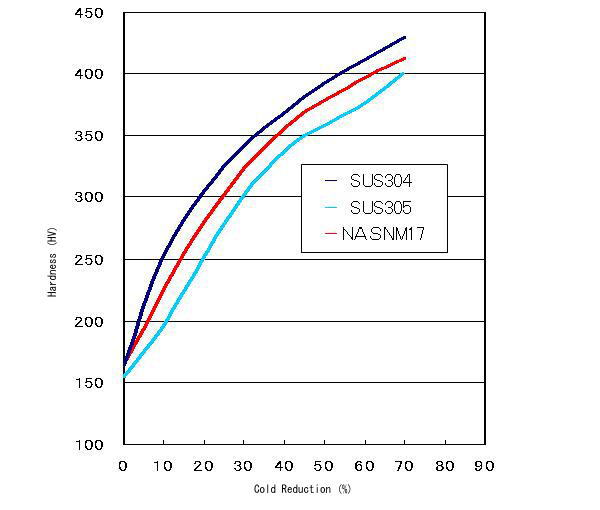

・Mechanical properties are the same as conventional Type304 stainless steel with both non magnetism and formability.

Chemical Composition

(%)

| - | C | Si | Mn | P | S | Ni | Cr | N |

| Example | 0.065 | 0.37 | 16.50 | 0.030 | 0.001 | 7.44 | 16.99 | 0.141 |

Physical Properties

| Density g/cm3 | 7.80 | |

| Specific Heat J/(kg・k) | 500 | |

| Specific Electrical Resistivity μΩ-cm | 75 | |

| Thermal Conductivity W/(m・k) | 14.5 | |

| Coefficient of Thermal Expansion 10-6/℃ | 30-100℃ | 16.0 |

| 30-300℃ | 18.5 | |

| 30-500℃ | 19.5 | |

| 30-700℃ | 20.4 | |

| Young’s Modulus MPa | 19.4×104 | |

| Magnetism μ | None | |

| Melting Point ℃ | 1,340~1,400 | |

Mechanical Properties (surface finish of 2D)

| - | Thickness (mm) |

0.2% Proof stress (MPa) |

Tensile strength (MPa) |

Elongation (%) |

Hardness (HV) |

| NAS NM17 | 0.70 0.40 0.25 |

314 326 335 |

643 656 675 |

52 54 52 |

157 154 154 |

| SUS 304 | 0.40 | 300 | 693 | 59 | 167 |

| SUS 305 | 0.70 | 245 | 552 | 55 | 136 |

Magnetic Permeability

Work Hardening Behavior

Workablity

Cold workability is the same as standard austenitic stainless steels.

| NAS NM17 0.7㎜ 2D | Erichsen Value | 11.5㎜ |

| LDR | 2.0 |

Corrosion Resistance

NAS NM17 provides comparable corrosion resistance to standard austenitic stainless steel such as Type 304.

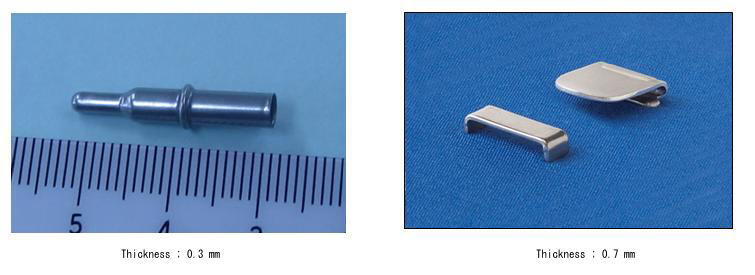

Examples of Forming

Application

NAS NM17 can be applied to metal parts for apparel industry and other various parts requiring non magnetism. It is more resistant in changing color and higher in strength than non magnetic copper alloys.